|

|

- Company Introduction

- We specializes in producing textile drying equipment such as tenter machine and coating machine. As a enterprise in textile machinery industry, we always demand ourselves, strictly strive to innovate and improve quality to meet the needs of customers.

|

|

- Characteristic (Standard Configuration)

-

No temperature variation among left,right and center by zig-zag arrangement motor & heater in each chamber

Increasing hot air volume by modifying chamber structure for improving productivity

Stop mark prevention damper(option)

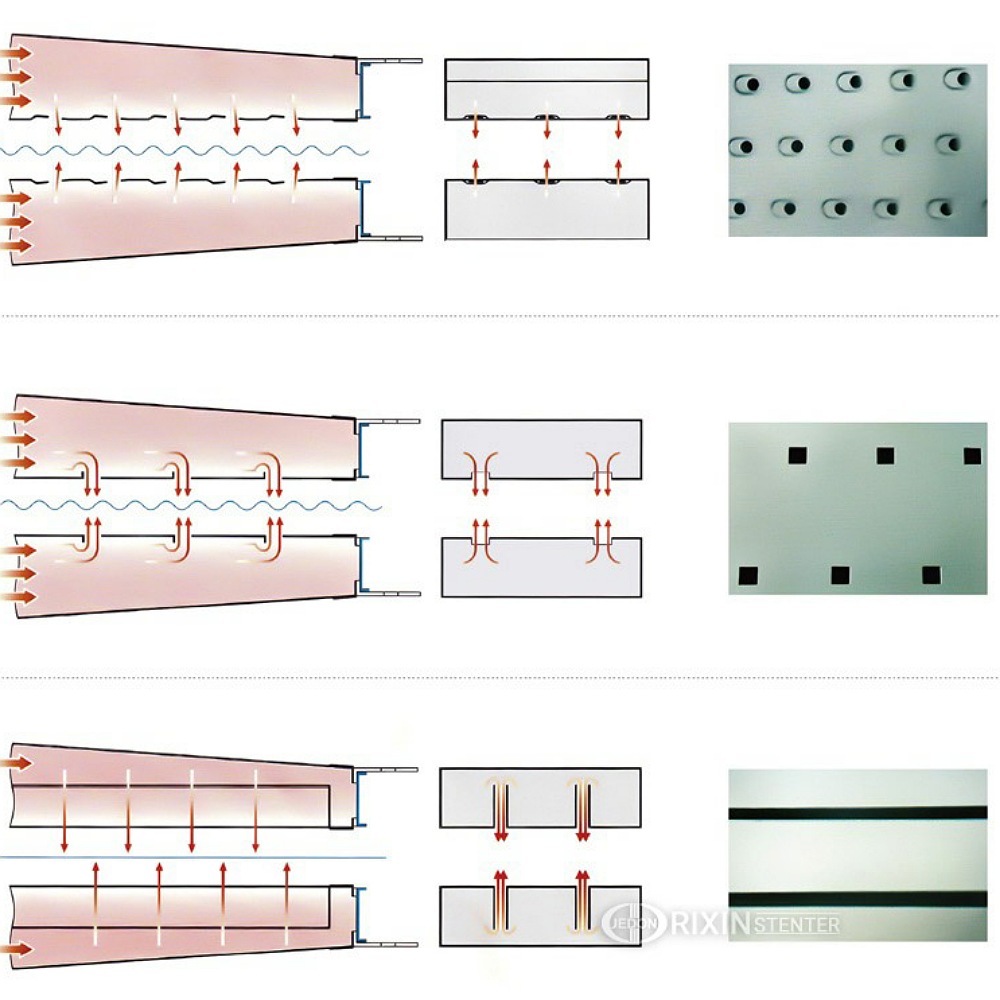

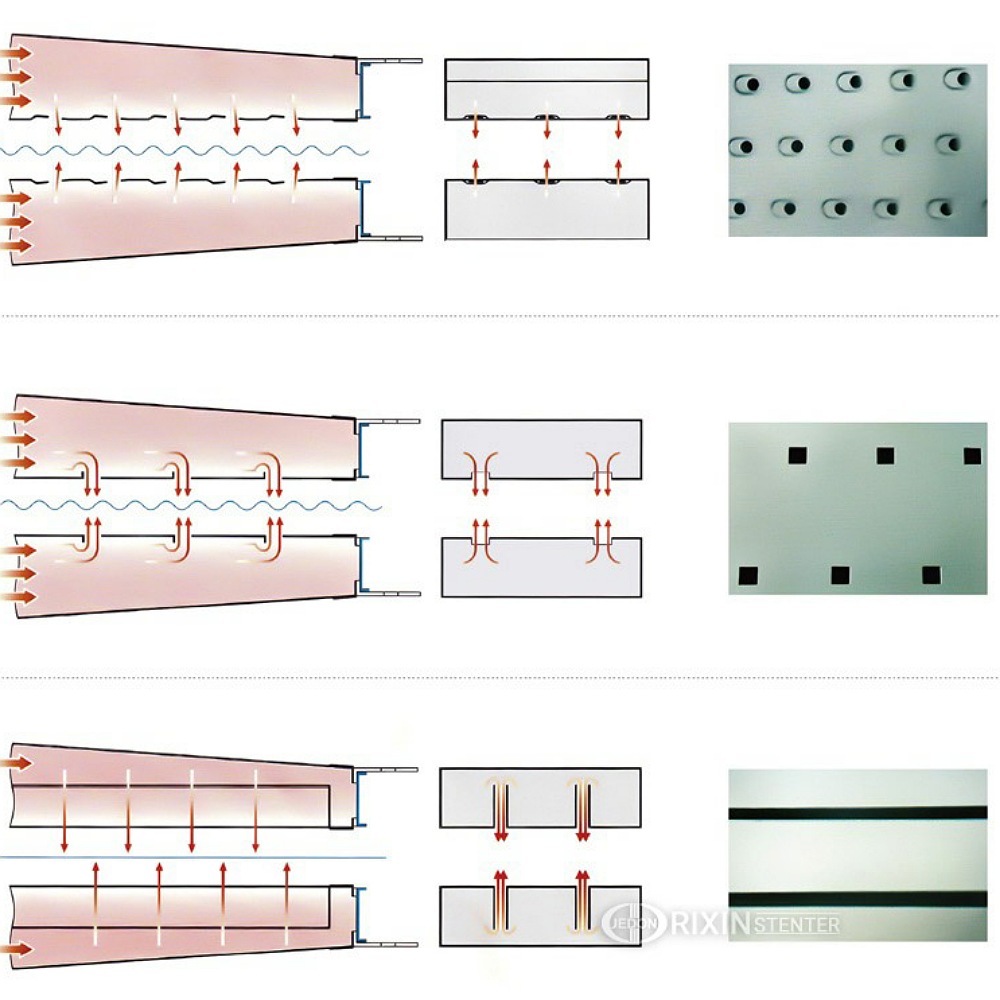

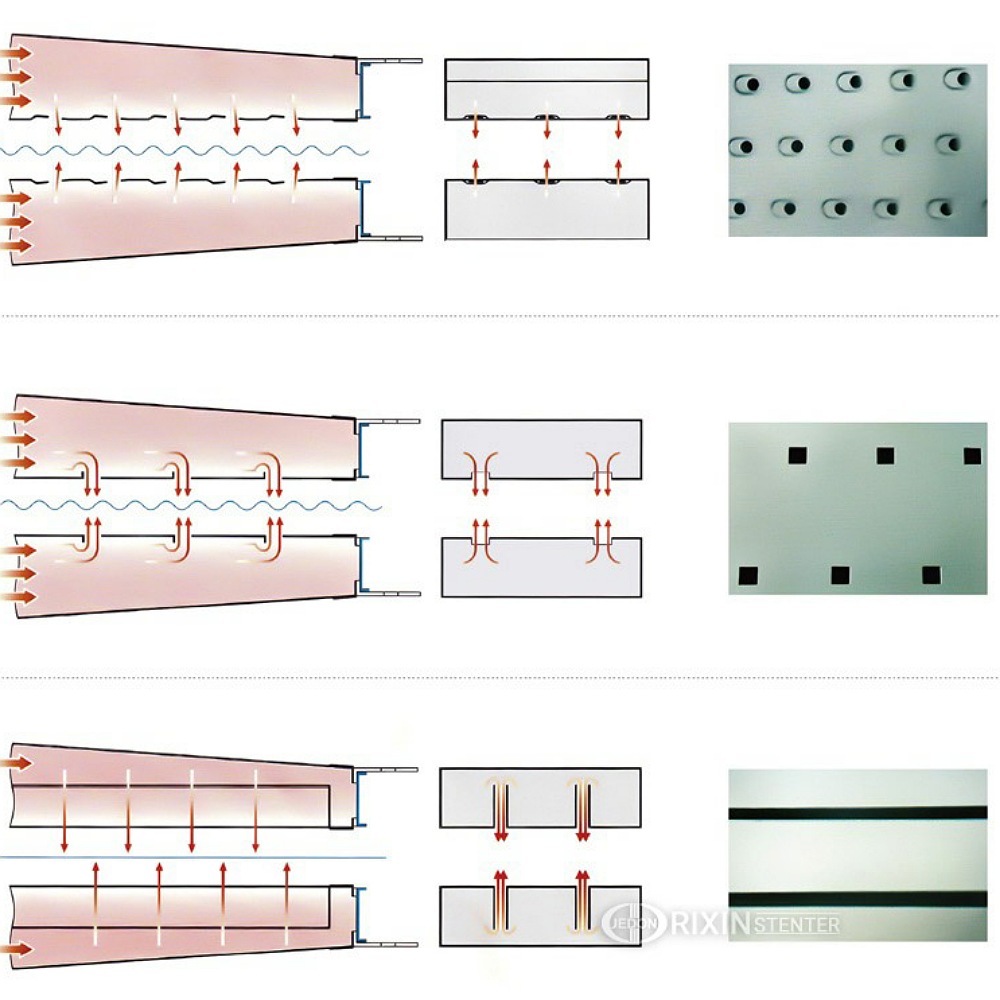

Various types of nozzle suitable for various kinds of fabric

Less tar by individual high efficient exhaust/Little fire hazards

Easy maintenance by reasonable inner-space in chamber

|

|

|

|

- MANGLE

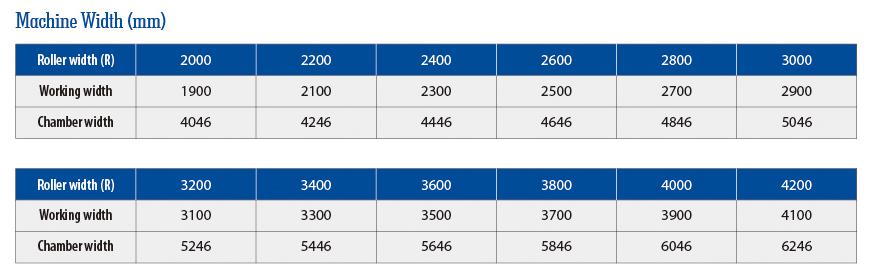

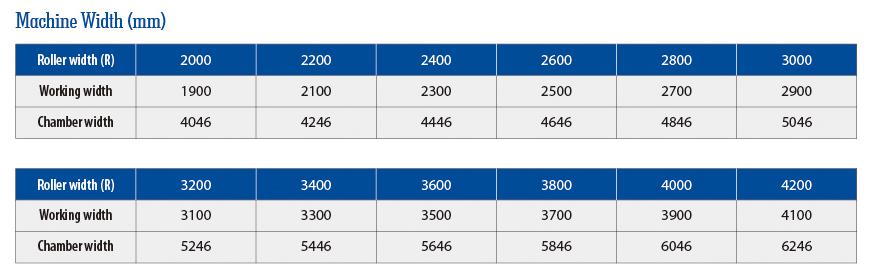

- High durability of mangle rollers by increasing diameter of roller as per the enlargement of roller width improvement of roller lifetime and pickup ratio even with wide width (max 4,400mm) by minimizing shaft or roller.

- Adequate selection of roller hardness and roller structure as per particular kinds of fabric.

|

|

|

- INFEED SECTION

-

Low Tension System

Prevent fabric slipping by increasing diameter of feed-in roller and over-feed roller.

Touch Roller and Manual weft straightner

Extended weft straightening range.

|

- OVER-FEED SYSTEM

-

Very accurate control of over-feed ratio by P.M.motor High durability, Range of over-feed ratio: -20%~+50% (to set by 0.1% unit) or -10%~+80%.

Easy operation for controller.Special design for gear box (No trouble)

Up & down control for over-feed roller on special process like coating.

|

![]()  |

|

|

|

- 3-Fingers Selvedge Uncurler

|

|

|

|

|

|

|

|

|

|

|

|

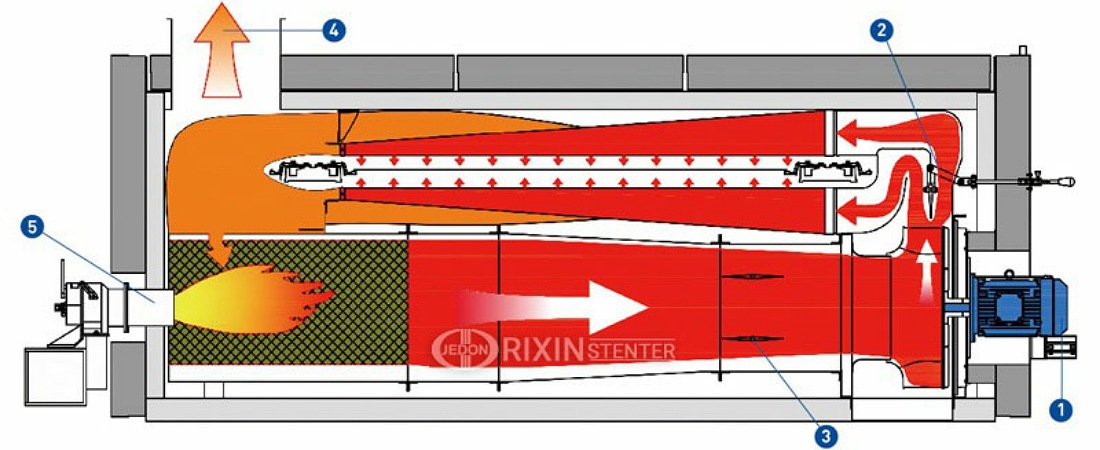

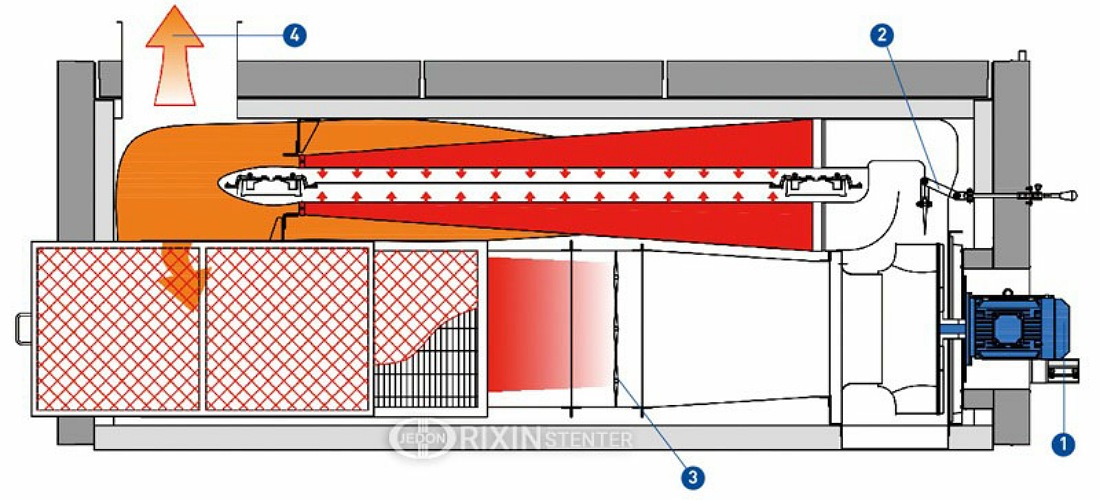

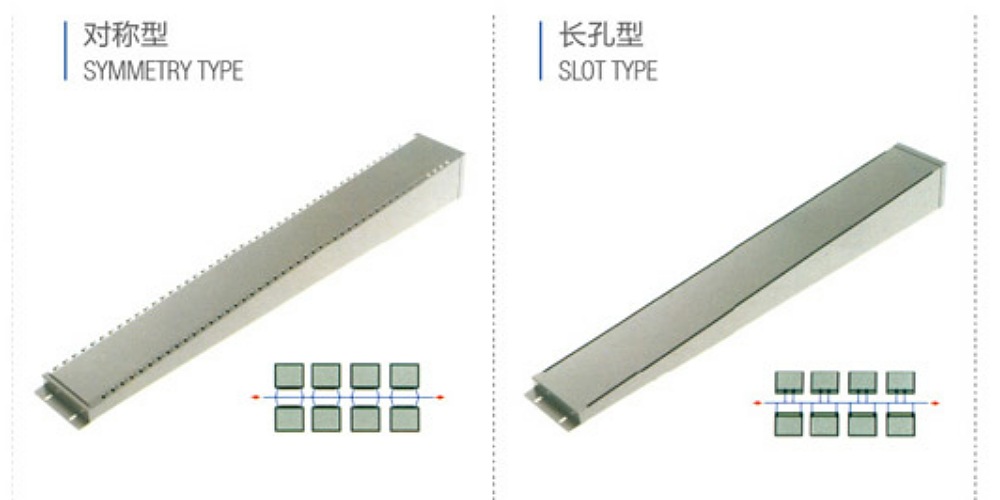

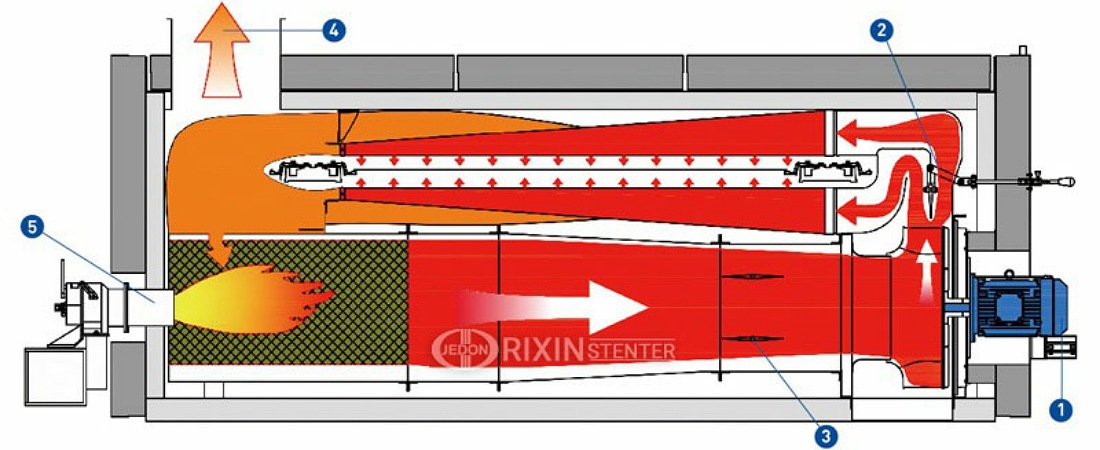

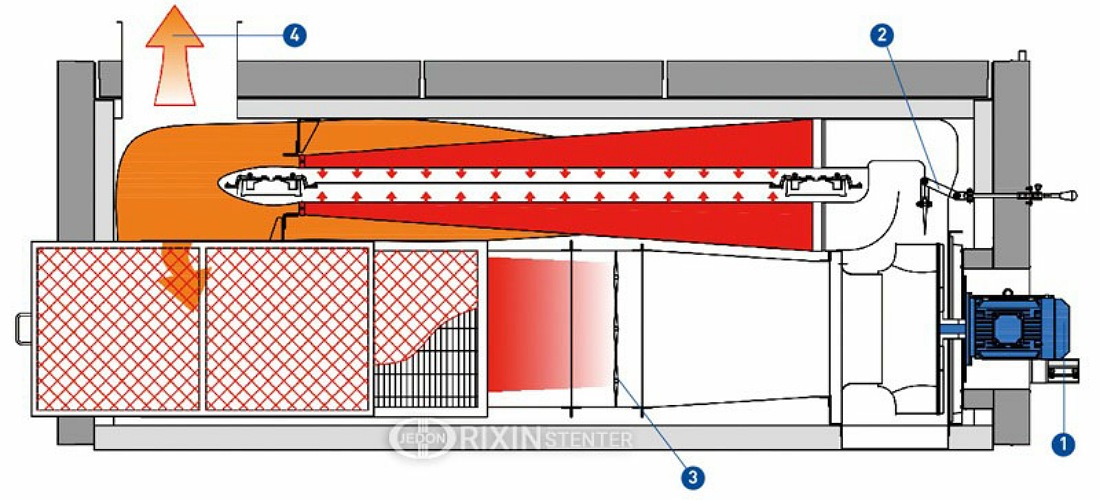

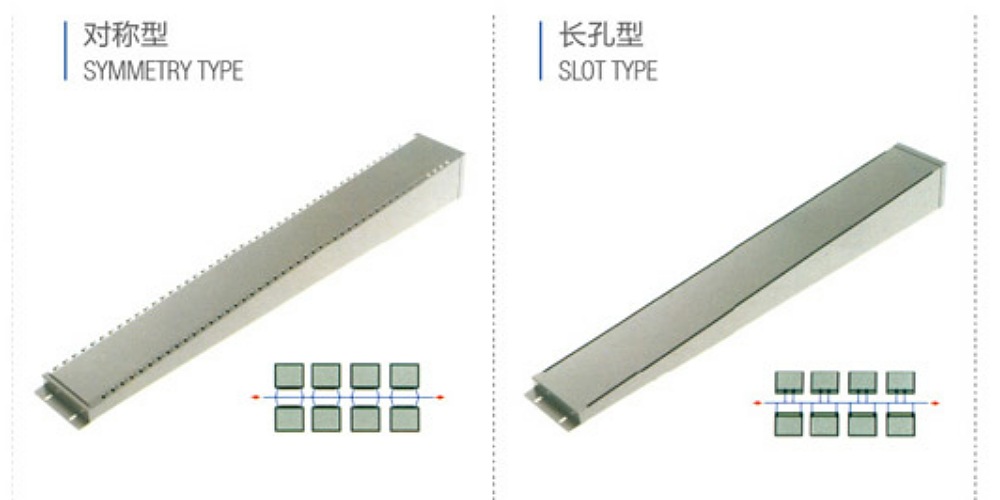

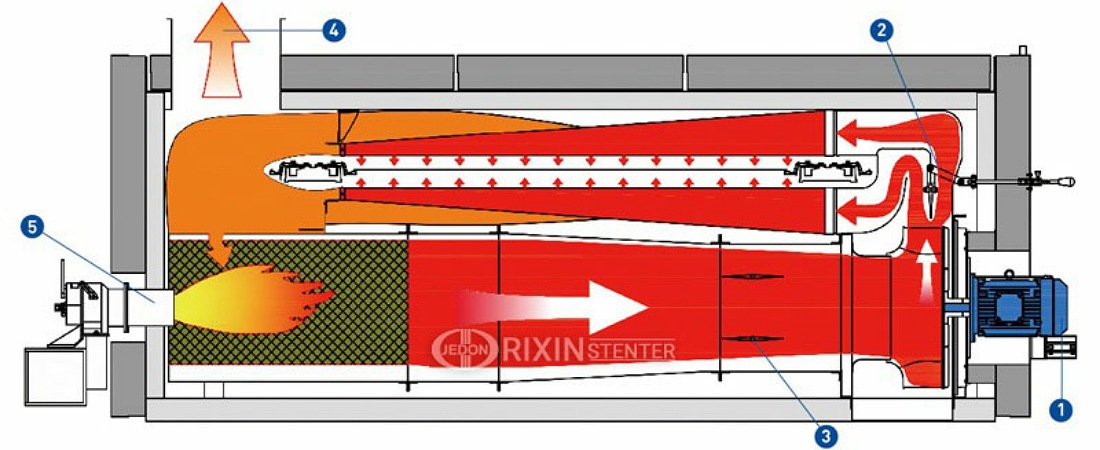

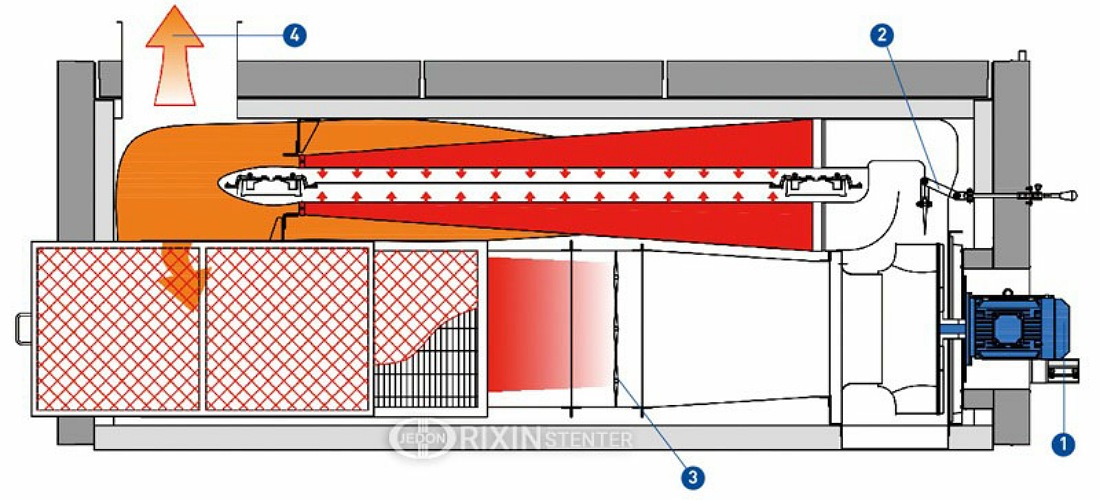

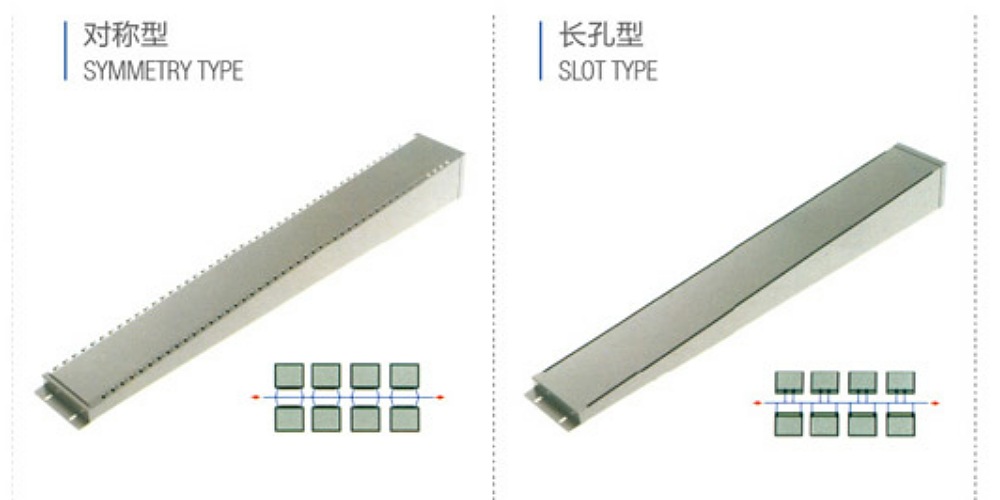

- CHAMBER

-

Air volume of Oval box is 10% Much More than square box

1.5x2M boxes are more uniform air jet

Ensure uniform density of fabric

Get a good texture.

|

|

|

|

|

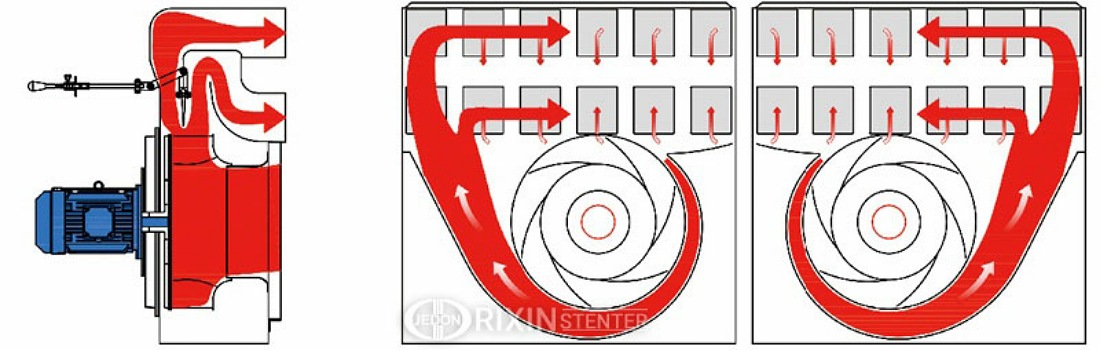

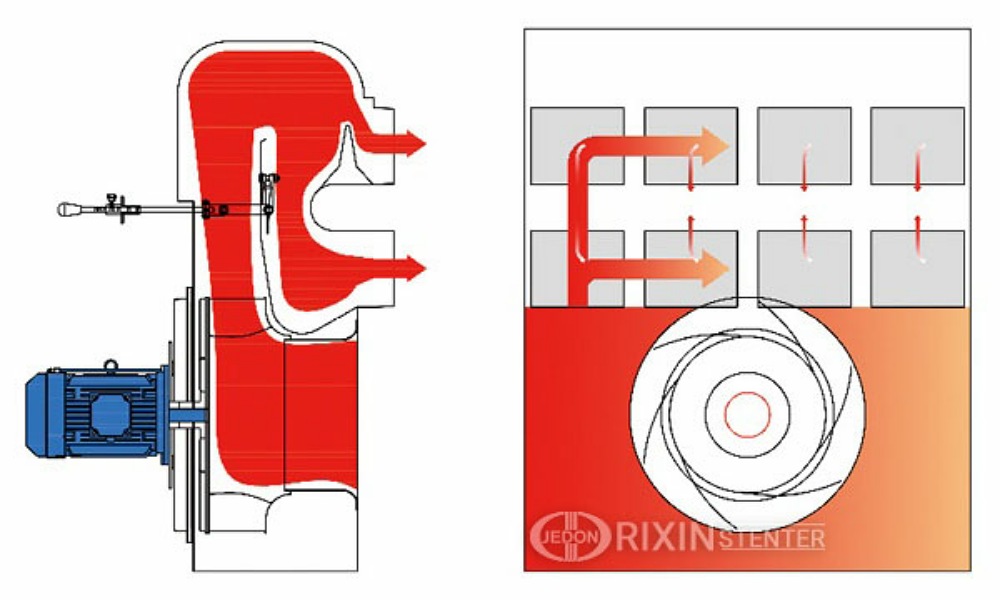

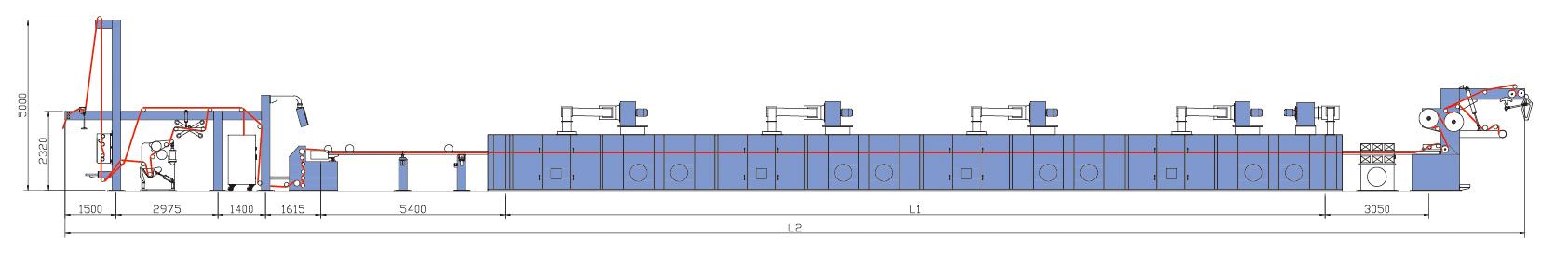

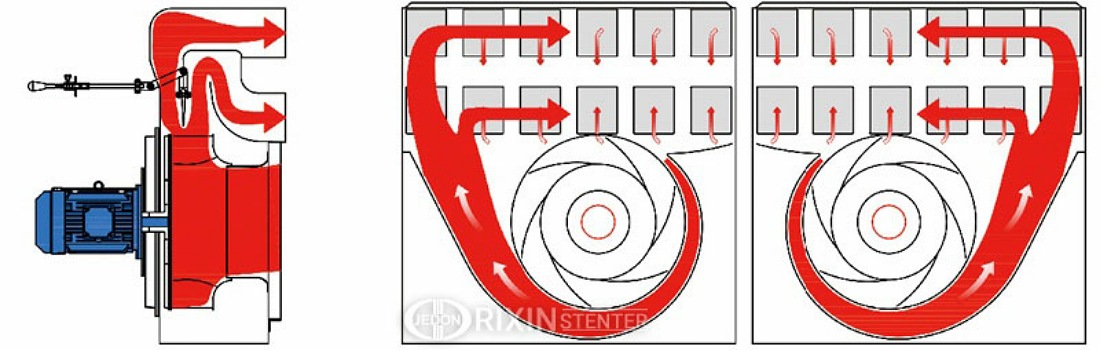

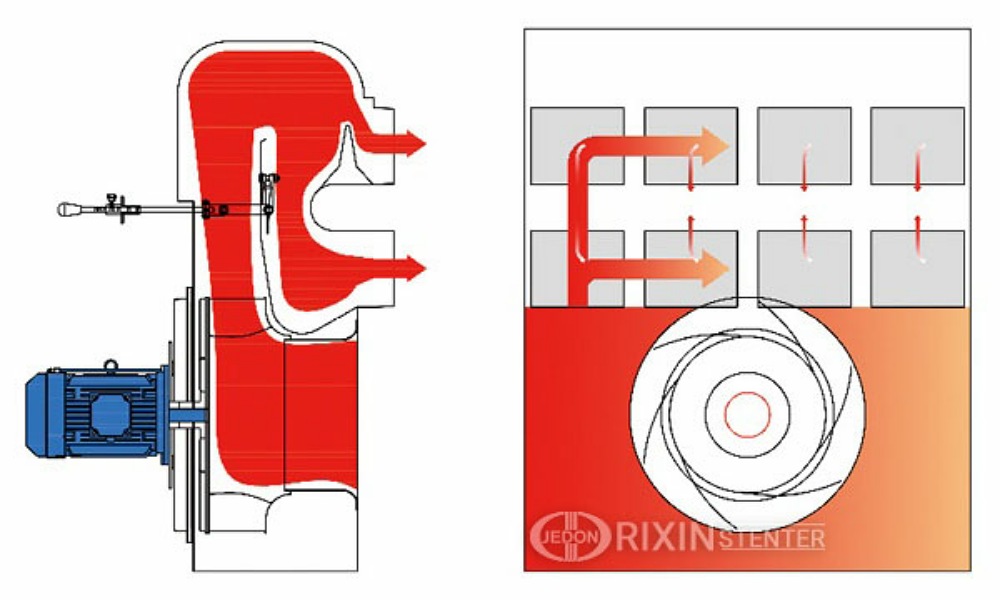

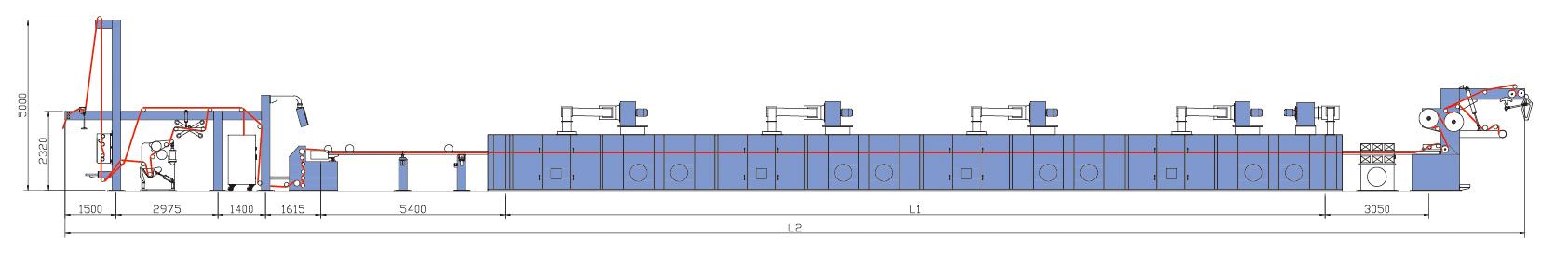

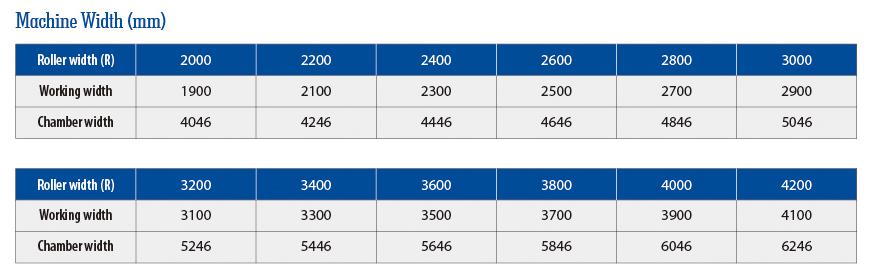

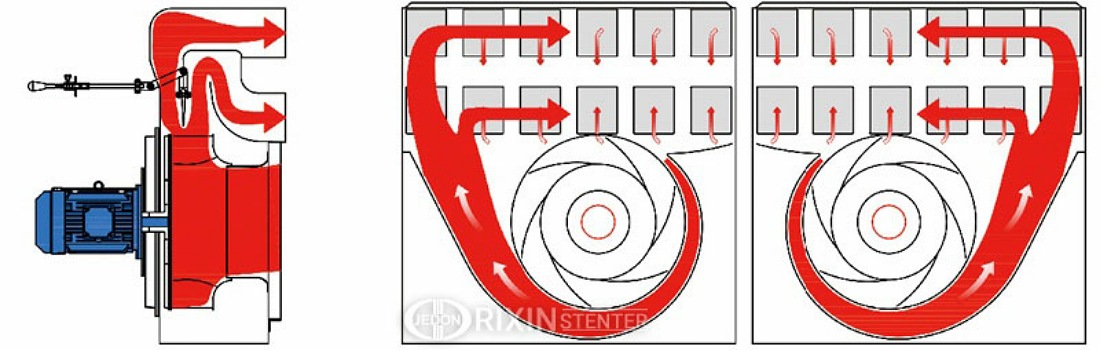

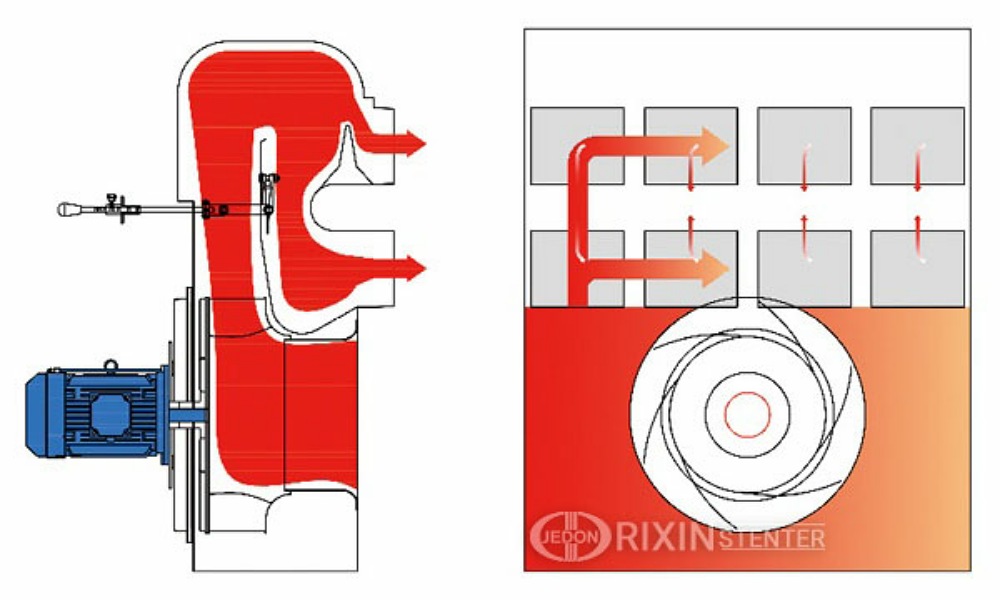

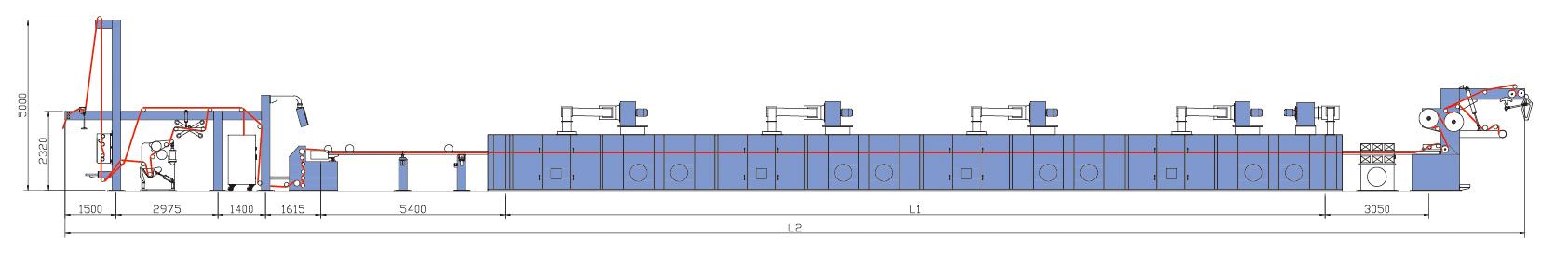

- Air volume increased by bigger fan increased circulation speed, lower chamber height 200mm for save energy loss.

- Easy maintenance and reduce time loss by making possible to enter chamber inside for repair and cleaning.

- Easy control of hot air distribution of upper & lower nozzle.

- Prevent stop mark on fabric in case of emergency stop.

|

|

Characteristic ( Standard Configuration)

- No temperature variation among left,right and center by zig-zag arrangement motor & heater in each chamber

- Increasing hot air volume by modifying chamber structure for improving productivity

- Stop mark prevention damper(option)

- Various types of nozzle suitable for various kinds of fabric

- Less tar by individual high efficient exhaust/Little fire hazards

- Easy maintenance by reasonable inner-space in chamber

- Excellent heat insulation,low heat loss,energy saving by special insulation board (thickness:150mm)

|

|

![]()  |

|

|

|

|

|